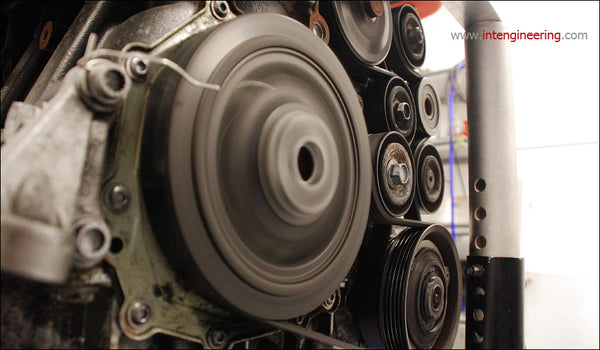

For the last few months, we've been working on various products for the VW / Audi 2.5L. After successfully installing it on our engine dyno, and getting the bone stock engine running on a Vi-Pec V88 ECU, we were able to start development work.

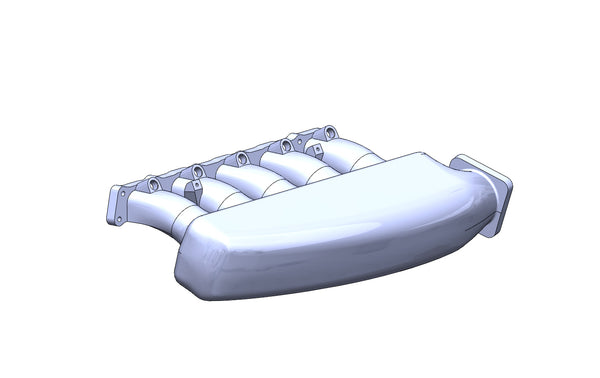

Since then, we've been working steadily on developing parts. Principally, our engineering staff has been working on a short runner intake manifold. So far, with just the addition of the manifold, we have been able to bump power output by about 40 horsepower- however development work continues. First we look at the valve sizes, cam lift curves, and other engine characteristics, and determine a baseline runner size and length. Then a manifold is carefully computer designed around these characteristics, and flow optimized using CFD.

However, this is basically just a rough draft... It's not too carefully detailed, as many changes are expected during the development phase. This model is taken and chopped into parts which make it modular. This allows us to create new prototype sections and test changes to the plenum, lowers, or runners, without creating entirely new prototypes every time. We call these development mules...

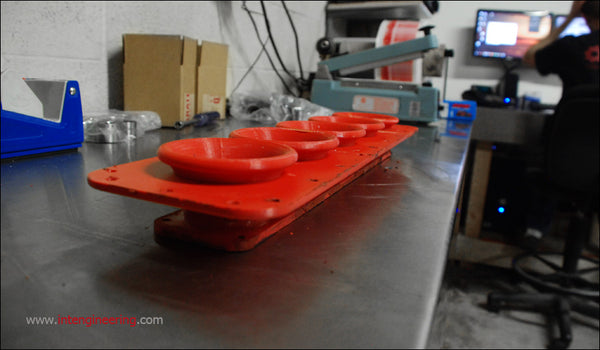

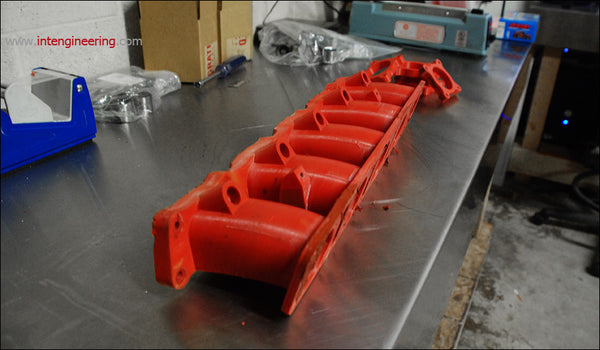

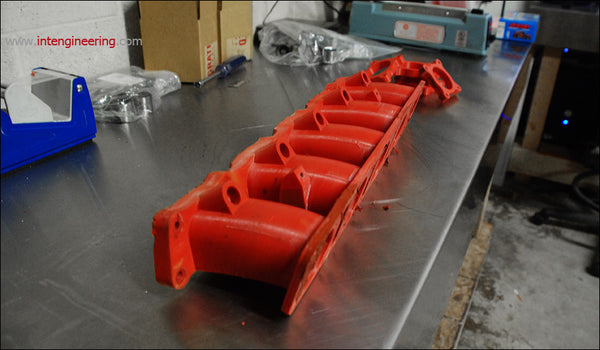

Next, our engineers use our Stratasys 3d printer to create functional, full scale prototypes out of ABS plastic... Through experience, we have determined the proper process to successfully run these parts directly on the engine. This gives us engine dyno power and flow results long before any designs are committed. Many companies would outsource this work and print only one manifold prototype to check fitment. In contrast, we typically will test as many as 20 refinements to a manifold design- everything from runner length, shape, size, and injector placement is checked... Below are some prototype parts from the development process of this 2.5L VW Part... Check them out!

Rapid prototyped ABS development mule on our VW 2.5L test engine... Note the modular construction.

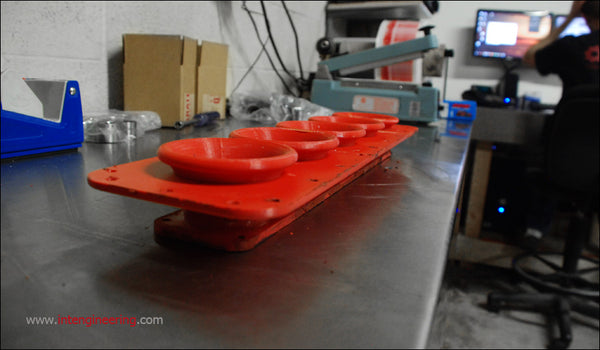

Here are some of the sections by themselves... You can see this particular one features a large diameter velocity stack with a very generous corner radius. Below it is a runner section- notice the injector placement is different- one is stock, the other one moved upstream somewhat. These sections are printed layer by layer out of actual ABS plastic... We have even used them on boosted engines before.

With the parts ready to go and assembled, dyno testing is the next main stage. We have been testing different configurations and designs for this manifold for several months now, and are getting close to finalized results. By using a programmable aftermarket ecu, we can ensure that the test conditions are fair for each run. Our dyno controls and measures dozens of data channels as well, including airflow, EGT, air/fuel ratio, oil and water temps, fuel flows, and much more. This gives our engineers the data required to determine how to proceed next!

Eventually, all of this will be combined into a finalized version of the manifold, and made ready for production. That version will be fully detailed out and optimized. A final complete manifold will be printed to check fitment on the car and confirm final power numbers before it goes to casting. Make sure to bookmark our blog for future updates as progress continues towards the final goal- tearing up the streets with a beautiful, American designed, engineered AND manufactured manifold!